Infrastructure

We are an ISO certified high-quality blanket supplier. Our manufacturing facilities are spread over a built-up area of 80,000 square feet which is divided into different sections for storage of yarn, testing of yarn, processing of yarn, manufacturing units, storage of fabric, quality control, etc. We are capable of manufacturing mink blankets, polar fleece blankets and supersoft mink blankets with variable patterns, with our well-planned infrastructure.

List of Machinery:

Raschel Knitting Machine

This machine relies on warp knits and is used to produce knitted fabric. It is used to knit polyester yarns coming from beams as parallel sheets into fabric by loop formation.

Warping Machines

This machine helps transfer yarn from a predetermined number of tubes or cones positioned on the creel onto a warper’s beam or a weaver’s beam.

Slitting Machine

The slitting machine is used to cut a large roll of material into narrower rolls.

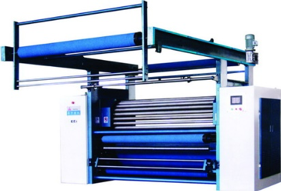

High speed Brushing Machines

The is used to give a peach finish touch to the surface of knitted fabrics and allows to minimize knitted fabrics curling and to maximize the production.

Double roller polisher

Gas powered machine that uses two 415-mm polishing rollers to remove excess unwanted oil, and give a polished and a shining effect to the fabrics

Single roller single touch polisher

Similar to double roller polisher but uses single 415-mm roller to remove excess oil from printed fabric in final finishing stage

Polycut shearing machine

Smooths the fabric by removing the fine protruding fibers on the surface of the fabric. This is achieved by passing the fabric through gas burners at a suitable distance to burn the pills off of its surface.

Razing machine

Used to treat the fabric surface with sharp teeth to lift the surface fibres, thereby imparting hairiness, softness, and warmth.

Flat bed printing machine

Automatic, flatbed advanced magnetic 8-colour printing machine with 14 printing heads to ensure printing of endless beautiful designs and colour combinations.

Loop ager

Helps in steaming of fabric at a very high temperature for publishing treatment post printing/ dyeing.

Washing machine

Used as part of final finishing process and is used to remove impurities from the surface of fibres, yarns and fabrics

Hydro

This machine is used for drying fabric with the help of centrifugal force. It uses an internal drum which rotates at high-speed creating a high gravitational force enhancing water extraction from fabric.

Drying machine

This machine is used post hydro-machine and is used to further dry the fabric before fabric goes onto brushing machine for final finishing

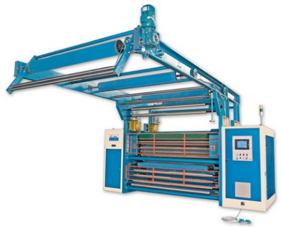

Embossing machine

This machine uses sharp heated emboss plates to print any emboss designs on the blanket; often is used as a final step pre-stitching

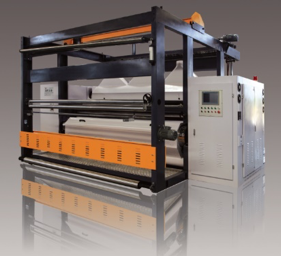

Pad dyeing

This machine is used to print single colour blankets and uses deep dying technology to ensure colour penetrates the fabric pile evenly and completely

Stitching and packing machines

Final step includes sewing the fabric into blankets form as per size requirements and stitching beautiful border satan onto the blankets.